Paint Protection Film is the most comprehensive form of protection you can apply to your vehicle to protect it from stone chips, small scratches, bird droppings, chemical stains, and a host of other environmental contaminants. If you are about to purchase a new vehicle, and you want it to keep looking like it does the day you buy it then paint protection film is the solution for you. Here’s what you should know about Automotive Paint Protection Film.

GETTING TO KNOW PAINT PROTECTION FILM: WHAT PPF DOES FOR YOUR CAR

Automotive Protective Films go by many different names: Clear Bra, Clear Mask, Invisible Shield, Clear Wrap, Stone Chip Protection, Car Scratch Protective Film, etc. The most common terms for car protective films are simply Paint Protection Film and PPF, and we’ll use those two terms interchangeably in this article.

Here’s the whole point of Automotive Protective Films: It keeps your car looking better for longer. That’s it. That’s what this is all about. Car Paint Protection Film is the most comprehensive form of defense you can establish between your car and all that can damage your car’s appearance. Because of Paint Protection Film’s high impact resistance, its application will protect your paint from chips and scratches caused by stones and road debris. The urethane film is resistant to corrosion and acidic contaminants, meaning that it creates a line of defense from chemical stains and etching caused by bird droppings, bug splatter, or mineral deposits and acid rain. It does not oxidize with exposure to the sun, and will guard your paint from fading caused by UV rays. The top layer of a quality film is made up of elastomeric polymers that return to their natural shape after being stretched or disfigured, giving the film a “self-healing” property. That means when light scratches are inflicted in the film, it absorbs the damage and returns to the texture and properties it had before the incident.

All that to say, applying a quality paint protection film is something you can do today in order to help maintain the look and quality of your car’s paint for years to come.

Now, let’s remember, while Paint Protection Film is powerful and it’s benefits are numerous, it is not a cure-all when it comes to keeping shiny cars shiny. Nothing will make your car bullet proof. There are rocks that can puncture the film. If bird droppings or bug splatter are allowed to sit on film for a long period of time, it can damage the film. After applying Paint Protection Film, you will still have to wash your car. There is no one-stop-shop solution to perfect and unending gloss. That’s not what Paint Protection Film promises. Rather, Paint Protection Film promises that after application, when the forces of nature fight against the depth and clarity of your car’s paint, the paint will fight back. You will add value to your car by protecting it from damage you could not have avoided otherwise. In the words we used earlier, Paint Protection Film keeps your car looking better for longer

WHERE DID PAINT PROTECTION FILM COME FROM? THE HISTORY BEHIND PPF

Whenever you’re getting to know someone or something, it’s helpful to get some background information. So how about a little bio on the technology behind paint protection film.

Automotive Paint Protection Film is a transparent, urethane material. Urethane technology was developed during the Vietnam War, when U.S. helicopters were crashing due to damage on the leading edge of rotor blades. The military worked with 3M to develop a technology that would be lightweight, but resilient, and could be replaced at the fraction of the cost of replacing an entire rotor blade (or a crashed helicopter for that matter). In the 1970s, the military expanded its use of urethane films to the noses of fighter jets, and because the technology has been so successful and efficient, 3M still manufactures a variety of urethane films for military and aerospace purposes to this day.

In the 1980s, NASCAR saw how urethane technology could be beneficial in protecting the front half of race cars. Advertisers pay a lot of money to get their decals plastered on the front of fast cars, and I’m sure they weren’t too keen on those decals getting peppered by rock chips.

During the 1990s, urethane films became available to the general consumer for automotive protection. Since then the technology has been continually refined and improved, and has been enthusiastically welcomed across the automotive industry. Today Paint Protection Films are OEM approved by virtually all automotive manufacturers.

WHAT IS USED TO MAKE PAINT PROTECTION FILM? THE TECHNOLOGY BEHIND THE FILM

If you’re going to wrap something around your new vehicle, you’ll want to know not only where it came from, but what it is exactly. Let’s talk a little bit more about what’s inside a sheet of Paint Protection Film. The key ingredient is urethane, a powerful and versatile polymer made from carbamate links. As a compound, it has unique attributes: It is lightweight and transparent, like plastic. But unlike plastic it is not brittle or susceptible to tears and cracks. It has a high resistance to impact, abrasion, and corrosion. It is also incredibly flexible, and can return to its natural shape after being stretched or disfigured.

Given the polymer’s diverse and advantageous attributes, it has a wide variety of industrial and recreational applications. Urethane is used in the household caulk with which you line your bathroom tiles, because it seals spaces from moisture and prevents the growth of mildew or fungus. It can also be found coating boats and underwater cables to prevent damage. It is used in various sporting equipment parts, from football pads to surfboard fins. Its strength and resistance to wear and tear makes it an ideal component for manufacturing and mining equipment. As we mentioned earlier, urethane is still used to protect various parts of military and aerospace equipment.

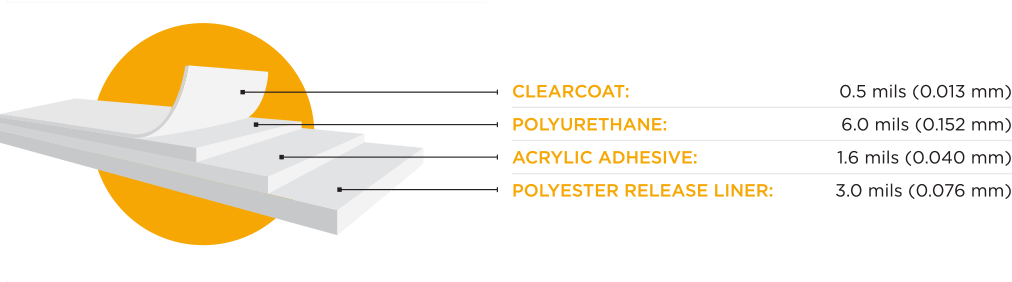

The applications of urethane as a polymer are broad, but today we are talking about your car, and for the benefit of your car, urethane serves as a central ingredient in a clear film around 8 mils (0.008 inches) thick.

In addition to the central layer made up of urethane (or polyurethane), a quality Paint Protection Film has at least two other layers. First, the top is lined with clear coat made up of elastomeric polymers. As we mentioned above, this is the part that enables a good film to heal itself from small scratches. But it does much more. The clear coat on a good film will have a low surface energy, which prevents organic compounds, like bugs or bird droppings, from bonding with the film.

Second, the bottom is lined with an acrylic adhesive that is designed to be flexible, so that it can be stretched and wrapped around every contour or your vehicle; durable, so that the film will not detach over time; and invisible, so that it will not affect the look of the paint.

ARE THERE ANY LIABILITIES? WHAT ABOUT YELLOWING, BLISTERING, OR PEELING?

After being properly applied, Paint Protection Film is invisible to the naked eye and does not inhibit the depth and clarity of your factory paint. But what about over time? If you’ve done some reading around the Internet, you may have encountered individuals documenting defects that have appeared in their PPF after a certain amount of time. In particular, some people who have purchased an after-market film have noted yellowing, blistering, and peeling. For you to make an informed decision, it’s important to know what’s behind each of these de generations and what you’ll need to do to avoid them.

YELLOWING

An early complaint against Paint Protection Film was that after time it began turning yellow, which, of course, has a significant impact on the look of a vehicle’s paint, especially for white cars. This complaint was particularly prevalent when Clear Bras first started being applied to consumer automobiles. After researching the matter, film manufacturing companies found that the yellowing effect came from the adhesive that was used to bind a film to the body of a car. UV exposure was oxidizing the adhesive, which lead to discoloration. Upon this discovery, companies began researching alternative adhesives, and began using the acrylic adhesives that are found on most films today. This newly developed adhesive is UV resistant, and will not oxidize or discolor. This effectively resolved the discoloration concern for Paint Protection Film. Today, if you put a sub-standard film on your car, it may use an inferior adhesive and lead to discoloration. But all quality professional film manufacturers, like XPEL, SunTek and LLumar, use a more recently developed adhesive that does not discolor due to UV exposure.

BLISTERING

A film is said to “blister” when small air bubbles are found underneath the film. The blistering effect has everything to do with the quality of application. Typically, an air bubble occurs because a contaminant is trapped under the film, creating separation between the body of the vehicle and the film. Overtime this can lead to growing bubbles under the film. A proper application process includes hairsplitting attention to the vehicle’s surface before any film touches paint. This includes washing, claying, and polishing. Moreover, a professional application center creates a controlled environment where the air can be filtered to remove contaminants that could potentially get trapped underneath the film. Thus, a sub-par film and unprofessional application can lead to blistering. But when a quality film is properly applied by an experienced technician, the risk is at most very minimal.

PEELING

Peeling is, of course, when the edges of a film begin to peel away from the paint. It can result from a sub-standard film or unprofessional application, but it is often the result of improper care. Specifically, if you are using a pressure wash to clean a car with Paint Protection Film, it is important to stay at least 12 inches away from the film, and particularly from any exposed edges. If a pressure washer is directed at the edge of the film, it can begin lifting the film, which leads to peeling.

In sum, the complaints against Paint Protection Film do arise from real-world situations. However, as we have outlined, these situations have specific causes that can be averted. If you purchase a high quality film (like XPEL Ultimate, Suntek Ultra or LLumar Platinum Paint Protection Film), have it installed at a reputable installer, and properly care for your protected vehicle, then the risk of defects like yellowing, blistering, or peeling are next to none. And if any of those things do occur, you will be covered by a ten year manufacturers warranty.

SUMMING IT UP: DRIVE PROTECTED

So when it comes to keeping your new vehicle looking new, Paint Protection Film is the most comprehensive and longest-lasting solution. If you have additional questions, look over our Frequently Asked Questions or browse some of our Paint Protection Film blog posts. Fill out our contact form if you have any questions or if you are ready to schedule an appointment.